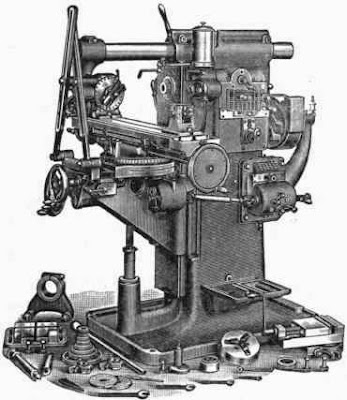

Milling is the procedure of cutting away material by feeding a workpiece past a spinning cutter having multiple teeth. The machine used for this procedure is known as a Milling machine. They are highly multipurpose because of their ability to perform a vast variety of operations

Milling is the procedure of cutting away material by feeding a workpiece past a spinning cutter having multiple teeth. The machine used for this procedure is known as a Milling machine. They are highly multipurpose because of their ability to perform a vast variety of operationsThese machines are not only limited to the variety in usage, but they also come in various sizes and control options. Milling machines can be operated by hand, mechanically or by total automation using Computer Numeric Controls (CNC).

Types of Milling Machines:

Milling machines are in two forms vertical and horizontal. These forms represent the arrangement of the cutter on the machine.

These machines are broadly classified into the subsequent types:

- Column and Knee Type Milling Machines: They are the most widely used class of milling machine and are normally used for common milling operations. In this type, the alignment of the milling cutter can be horizontal or vertical.

- Bed Type Machines: They are more rigid and are used mainly for high fabrication work. The alignment of the milling cutter is upright.

- Planer Machines: This type of milling machines is almost similar to bed type machines. The difference between them is that planer machines have multiple cutter heads.

- Tracer Controlled Machines: They represent the latest in milling machine technology and are used to produce complex parts in the automotive as well as aerospace industry.

Other than the ones mentioned above, there are a few more subtypes like - C-Frame, Turret mills, Ram type mills, Boring mills etc.

As the technology is advancing, usage of manually operated milling machines has almost come to a halt. The CNC machines now provide better accuracy and quality in fabricating products. Also, human labor is reduced because a single person can control multiple CNC machines. These machines can work non-stop and only need to be switched off for occasional maintenance.

Although milling machines started evolving from rotary fillings, since the 1800’s, they still continue to evolve and it is expected that the future holds even more sophisticated and yet more productive machines.

No comments:

Post a Comment